Powder Coated Car Parts

At Maldon Shot Blasting & Powder Coating Ltd, we specialise in delivering high-quality, durable finishes for automotive components, with a strong focus on longevity and attention to detail. Our approach is built around doing the job properly the first time, ensuring results that stand the test of time and perform far better than traditional stove or wet paint systems.

Powder coating offers exceptional resistance to chipping and wear, making it an ideal solution for automotive parts exposed to regular use and harsh conditions. Each component undergoes a thorough blast-cleaning process, followed by the application of a self-healing primer that is partially cured. A polyester top coat is then applied while the part remains warm, allowing for improved adhesion and enhanced coverage — particularly in joints, corners, and other hard-to-reach areas.

We regularly coat a wide range of items including suspension components, wheels, and interior parts, all of which receive the same meticulous preparation and finishing process. For moving parts or components prone to stone impact, we recommend Plascoat®, a highly flexible and resilient coating. This specialist finish provides excellent protection against stone chipping while also offering strong resistance to oil-based fluids and many common automotive chemicals.

Any general repair work required can be completed in-house where appropriate. For specialist tasks beyond our scope — such as structural welding — components are referred to trusted local engineering partners, ensuring every project benefits from the right expertise and maintains our high standards throughout.

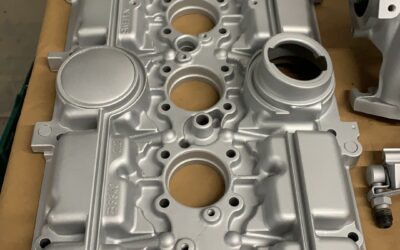

Some of our recent work….

#Rovers3.5 V8

Nice to see work items keeping to the original finishes.

Safe, Experienced Hands

After some 25 years of carrying out this type of work you can be sure that your engine and car parts are in safe experienced hands.

Practice on 1000s of Car Parts

MSB offers years of experience and fine attention to detail.

Triumph ready to go off to the body shop…

Bringing this Triumph back to life.. Blasted and primed, ready for the paint shop.

Cerakote ceramic coatings offers good protection along with a pleasing & reliable finish…

Cerakote ceramic coatings offers good protection along with a pleasing & reliable finish…

Old style number plate lettering…

Old style number plate lettering cleaned prepped and finished in a protective clear coat ceramic coating…

Plasma coated topped off with a ceramic coat

Plasma coated topped off with a ceramic coat and includes a full two-year guarantee. Extends life of the parts coated, reduces heat radiation by up to 30% and in some cases increases performance.

Ceramic coating headers and exhausts

Looking to ceramic coat headers or exhausts, we have a range of products to cover most requirements. Our work also includes a two-year guarantee in most cases.

More examples of our Ceramic Powder Coating…

More examples of our Ceramic Powder Coating…

Examples of our High Temperature Coating Work

Here are some examples of our High Temperature Ceramic Coating, recently produced in our workshop…

Ceramic Coated Manifold

Here is a fine example of a high-gloss Ceramic Coated Manifold

Although this manifold has seen better days we have extended its life and efficiency by blast cleaning and applying our plasma coat system, this will help to reduce heat radiation and offer protection from corrosion and help with metal fatigue.

Powder coating is one of the most advanced coating processes available and offers a long land durable finish.

Powder coating is a method of applying a decorative and protective finish to a wide range of materials and products.

The dry powder coating process involves electro statically charged that are sprayed onto a electrically grounded surface. The substrate is then heated and cured while the powder is baked on. The result is a uniform, durable,high-quality finish with exterior durability, Polyester powders are particularly resistant to ultra violet radiation.

There is a good Colour selection with dead mat to high gloss finishes available. A range Textured finishes and special effects are also available.

The Powder coating process is environmentally safe with virtually no VOC’s (Volatile Organic Compound)_released during the application and curing of the powder.

Why does it need shot blasting?

In short, it removes all contaminants such as rust, old paint etc and gives a good canvas and key to start the powder or painting process,and at the same time, it normally reveals any problems such as corrosion weakness or broken weld joints. Good preparation is paramount to a good long lasting finish.

When products do not need blast cleaning our new three stage cleaning & phosphate machine will be employed this further ensures a clean and etched surface for any powder or paint to adhere too.

Phosphating Follow the link below for further information.

http://en.wikipedia.org/wiki/Phosphating

How can we offer our unique warranties.

Simple by using the correct methods and high quality materials and experienced staff along with quality plant & equipment. Please do not be fooled by some who offer a cheap job, we have seen the results and they are not pretty. It will cost you more in the long run. Do It once do it right.

We also offer Aqua and bead blast cleaning for the more gentle approach to valuable products.

Read More How is Powder Coating Done?

Various Powder Coated Car Parts by MSBPCL

Engine Parts Black Chrome

Porsche silver powder coat

Zinc metallisation coatings offer long term protection for car chassis, car panels etc…